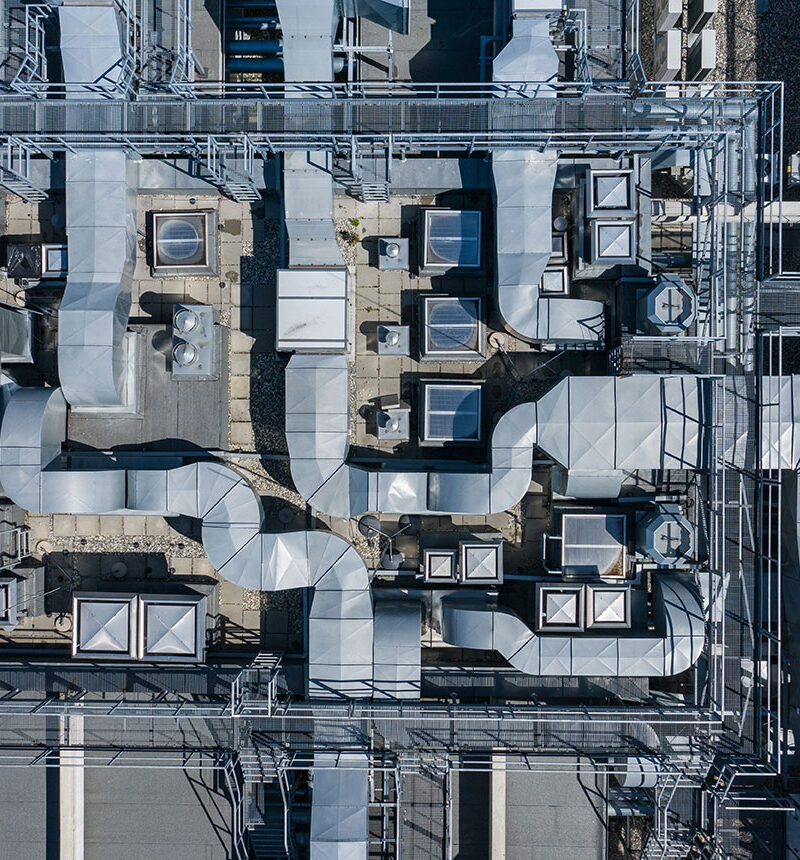

Why SUNISTA for HVAC

A group diversified into various segments now led by a young team of professionals from the gateway of pharma i.e Mumbai.

Team Sunista consists of young qualified engineers who hail from a few of the parent-renowned organisations in the HVAC sector. They bring extensive technical knowledge & rich experience in executing projects in different sectors across India as well as overseas. The team is having the quality to assist with the requirement from the design stage till the execution of the complete project. We are backed by our own consultancy team & flexible enough to work as per consultants’ guidelines. As the project gets commissioned the group is committed to providing services for a certain time frame decided which helps the customer engineering team to get familiar with the system installed. The group also provides training programmes on new technology in the HVAC systems with its channel partners across the Indian subcontinent.

Validation & Qualification in HVAC system

The safety of personnel and efficacy of the material including raw ingredients, in-process goods and finished products as well as machinery in the pharmaceutical industry is majorly impacted by the air ventilation quality within the industry.

HVAC system stands for Heating, Ventilation and Air Conditioning system, which ensures the optimum quality of the air environment as directed by regulatory authorities. The performance of the HVAC system is ascertained by conducting validation of this system within a specified duration. Validation of the HVAC system is achieved at three levels such as installation qualification

(IQ), operational qualification (OQ), and performance qualification (PQ); Which is subject to provide documented evidence about the accuracy of results produced by it.

The validation of the HVAC system involves systemized and assembled documents of its functional specifications such as design drawings, plans, and specifications; followed by a validation master plan involving testing, adjusting, and balancing (TAB); and finally, the start-up reports. The parameters analysed are airflow velocity, airflow pattern, air changes per hour,

filter leak test, particle count, viable monitoring, filter integrity test, pressure difference, recovery test for temperature and humidity, temperature and humidity uniformity, and fresh air determination.

Compliances Followed:

• Controlled Conditions in accordance with Schedule M, GMP, WHO and FDA standards.

• European Good Manufacturing Practices (EuGMP).

• Design Standard Followed by us:-

• ASHRAE (The American Society of Heating, Refrigerating and Air- Conditioning Engineers)

• SMACNA (Sheet Metal and Air Conditioning Contractors’ National Association)

• NFPA (National Fire Protection Association)

• IECC (International Energy Conservation Code)