A static pass box is designed to transfer material between clean environments which are equally clean and designed to work with minimal personal movement. A static pass box cannot be used to transfer material between a clean area and a non-clean area.

Specification & Features:

- Material: SS 304

- Surface Finish: Matt

- Internal Size: 750mm (L) X 450mm (W) X 900mm (H)

- One stage filtration

- Double walled flush glass view panels provided with doors, Handle and hinges

- U.V. Light

- Floor mounted construction with three side wall structure

- Support Stand for Mounting the Pass Box

- Flange for filling the gap between the pass box and the clean room wall

A dynamic pass box is a box which is designed to transfer material from an unclassified area to a controlled area and has got interlocked doors located on both sides with necessary filter and technical arrangements which prevents contamination transfer in controlled environment.

Specification & Features:

- Two stage filtration, EU6-Prefilter (95% down to 5 micron), EU14-HEPA Filter (99.999% / AZ 0.3 Micron)

- Dynamically balanced motor – blower facilitated with suspension arrangement to minimize the WC noise level

- Double walled flush glass view panels provided with doors, SS Handles and SS hinges

- Internal Covings for easy cleaning, Door interlocking with Electro-magnetic Interlocking

- Differential Pressure Gauge: 1 No. On/Off Switch for Motor & DOP Test Port

- U.V. Light with Hour Meter with interlocking arrangement to put-off U.V. Light if any of the door opens

- Floor mounted construction with three side wall structure & Door Drop Seal

- Support Stand for Mounting the Pass Box

- Flange for filling the gap between the pass box and the clean room wall

- Audio / Visual alarm for blower tripping with Fault Acknowledgement & Reset Switch

- Clean Down Timer with Operation Hold Indicator & interlocking to put on fluorescent lights only after clean down time over

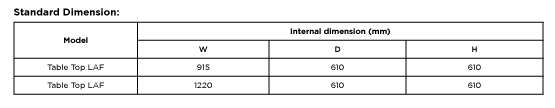

A laminar flow cabinet is an enclosed box designed to prevent contamination of Chemicals, Pharmecutical samples, or any particle sensitive materials. In a laminar flow Air is drawn through a HEPA filter and blown in a very smooth way. The cabinet is made in such a way using high grade of stainless steel and constructed with cnc and nc machines for smooth edges and no gaps ensures collection of particles. Laminar flows can be both horizontal and vertical configurations. These cabinets have a UV – Germkill lamp for sterilization of cabinet before perfroming an operaion.

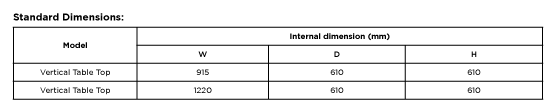

Specification & Features:

- MOC: SS304, SS316 and SS316L or customized execution

- Stand and worktable: SS304, SS316 and SS316L or customized execution

- Back panel: SS304, SS316 and SS316L or customized execution

- Side panel: Flushed glass

- Pre-filter: EU-7

- Final Filter: H-14

- PAO port

- Mechanical differential gauge across final filter

- Ventilator

- LED Light

- Electrical control system with push button and indicators

- Air flow visualization

- Air Cleanliness Level ISO – 5

- Noise Level: Less than 70db A when ambient is not more than 55db A

- Air Velocity: 0.45mps (± 0.05mps)

- Air Flow: Vertical

- Light Intensity: 250-300 lux

- Air flow visualization

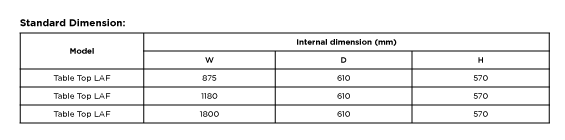

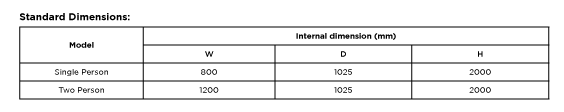

Specification & Features:

- MOC: SS304, SS316 and SS316L or customized execution

- SS worktable

- Cabinet support stand with leveling pads

- Side glass panel

- Pre-filter: EU-7

- Final Filter: H-14

- PAO port

- Mechanical differential gauge across final filter

- Ventilator

- LED Light

- Standard electrical control system with push button and indicators

- Switch socket

- Air Cleanliness Level ISO – 5

- Noise Level: Less than 70db A when ambient is not more than 55db A

- Air Velocity: 0.45mps (± 0.05mps)

- Air Flow: Vertical

- Light Intensity: 250-300 lux

A biosafety cabinet—is an enclosed, ventilated laboratory workspace for safely working with materials contaminated with (or potentially contaminated with) pathogens requiring a defined biosafety level. Several different types of BSC exist, differentiated by the degree of biocontainment required

Specification & Features:

- Filters series- Fine (5 µ) and HEPA (0.3)

- Pre Filter – Make: AAF

- Hepa Filter, Make: AAF or Equivalent, Efficiency- 99.997 down to 0.3µ

- Gaskit – Self Adhesive Neoprene Gasket

- Sealant – Epoxy Based, Non Soluble

- Coving – SS coving

- Air velocity – 90 ±20 FPM

- Class -100

- Blower type – AC Centrifugal Type (Dual In late), Impeller (Aluminum/GI)

- MOC Housing -(GI)

- Make of Motor -GE /EBM-Crompton /equivalent

- Air flow type- Vertical

- Light Fixtures- Philips/Anchor/Roma or equivalent

- Gas Cock – Standard

- Electrical Sockets- Philips/Anchor/Roma or equivalent, 230V, 50 Hz,Single Phase

- Magnehelic Gauge

- Diff. pressure across filter (Range)- 0-50MM WC

- Grills -SS mat finish protective grill for HEPA & Pre filter

- DOP Port -Std

- Noise level-65±5 db

- Door at front side- U.V. Protected Acrylic Door with Movable Vertical Automatic

- Magnehelic Gauge

- Diff. pressure across filter (Range)- 0-50MM WC

- Grills -SS mat finish protective grill for HEPA & Pre filter

- DOP Port – Std

- UV Light: Philips

- Hour Meter: inbuilt in controlle

It is stand-alone system designed to provide protection to products, personnel and environment during sampling, dispensing, grinding and filling operation. It ensures ISO 5 cleanliness level within safe working zone inside booth and typical scavenging air flow pattern ensure that there is reasonable protection to operator and environment.

Specification & Features:

- MOC: SS304 / SS316 or customized execution

- Side panel: Rigid SS 304 double wall

- Pre-filter: Eu-4

- Intermediate air filter: Eu-7

- Final Filter: H-14

- Exhaust HEPA: H-14

- PAO port

- Mechanical differential gauge across pre, intermediate and final filter

- Ventilator

- LED Light

- Electrical control system with push button and indicators

- Switch socket

- Service access: Front or back

- Dedicated control panel

- Drag shield

- Air cleanliness level: ISO 5

- Air Flow: Vertical re-circulatory

- Air flow visualization

- Noise Level: Less than 70db A when ambient is not more than 55db A

- Light Intensity: 250-300 lux Air Velocity: 0.45mps (± 0.05mps

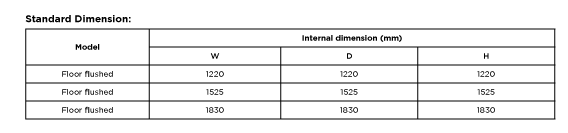

Air showers are specialized enclosed antechambers which are incorporated as entryways of cleanrooms and other controlled environments to reduce particle contamination. Air showers utilize high-pressure, HEPA- or ULPA-filtered air to remove dust, fibrous lint and other contaminants from personnel or object surfaces. The forceful “cleansing” of surfaces prior to entering clean environments reduces the number of airborne particulates introduced.

Specification & Features:

- MOC: GI powder coated, SS304, SS316 and SS316L or customized execution

- Front door: Doubled wall SS doors with flush glass view panel, hinges & handles

- SS perforated floor

- Door closure

- Air Nozzle

- Electromagnetic doors interlock

- Air pre-filter: EU-7

- Final Filter: H-14

- LED Light

- Air Flow: Turbulent

- Mechanical differential gauge across filter

- Emergency switch inside air shower

- Ventilator

- Air Velocity: 4000 – 5000 fpm

- Light Intensity: 250 – 300 lux

- Air Flow: Turbulent

A de dusting booth is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas. Designed to handle high-volume dust loads, a dust collector system consists of a blower, dust filter, a filter-cleaning system, and a dust receptacle or dust removal system. It is distinguished from air purifiers, which use disposable filters to remove dust.

Specification & Features:

- MOC: GI powder coated, SS304, SS316 or customized execution

- Doors: SS rolling shutter, high speed non-metallic shutter or antistatic PVC curtains

- Motorized roller conveyor

- Air Nozzle

- Shutter doors interlock

- Pre-filter: EU-5

- Intermediate air filter: EU-5

- Final Filter: EU-7

- Mechanical differential gauge across filter

- Ventilator

- LED Light

- PLC / HMI based control system

- Emergency stop

- VFD

- Dust collection tray

- Air Velocity: 4000 fpm

- Air Flow: Unidirectional (single pass)